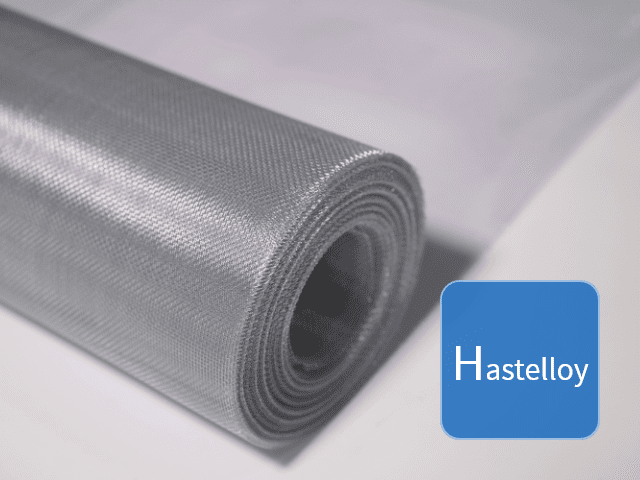

Plain Weave Mesh

Boedon, Weaving for Sieving & Filtering

Hastelloy woven mesh is a kind of metal woven mesh made of corrosion resistant nickel alloy. It features corrosion resistance, acid and alkali resistance and high temperature resistance, and is widely used in pharmaceutical manufacturing, chlorination devices, pesticide processing, incineration scrubber devices , etc.

According to different chemical compositions, hastelloy is divided into hastelloy B, hastelloy C22, hastelloy C276 and hastelloy X. Hastelloy B is a nickel-molybdenum based alloy that is highly resistant to corrosion in reducing environments like hydrochloric acid, and is often used in bearing assembly, ballast resistors, etc. Hastelloy C22 is a nickel-chromium-molybdenum-tungsten alloy that offers optimum resistance to reducing and oxidizing environments. It is often used in cellophane manufacturing, chlorination units, wastewater treatment, etc. Hastelloy C276 is a nickel-molybdenum-chromium alloy suitable for acid gas applications and is often used in scrubbers, dampers and flue gas desulfurization in pipeline. Hastelloy X is a nickel-chromium-iron-molybdenum alloy known for its excellent heat resistance, corrosion resistance, and oxidation resistance.

| Type | C | Co | Cr | Cu | Fe | Mn | Mo | Ni | P | S | Si | Sn | V | W |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H-B | 0.12 | 2.5 | 1.0 | – | 6.0 | 1.0 | 26.0–30.0 | Rem. | 0.01 | – | 0.03 | – | 0.6 | – |

| H-C22 | 0.015 | 2.5 | 14.5–20.0 | – | 2.0–6.0 | 0.5 | 12.8–14.5 | Rem. | – | 0.02 | 0.08 | – | 0.35 | – |

| H-C276 | 0.02 | 2.5 | 14.5–16.5 | – | 4.0–7.0 | 1.0 | 15.0–17.0 | Rem. | 0.03 | 0.03 | 0.08 | – | 0.35 | 3.0–4.5 |

| H-X | 0.08 | - | 17.0–20.0 | 1.0 | Rem. | 2.0 | – | 34.0–37.0 | 0.03 | 0.03 | 0.75–1.50 | 0.025 | – | – |

| Item | Mesh (Wires/ in.) | Wire Diameter (in.) | Width of Opening (in.) | Open Area (%) |

|---|---|---|---|---|

| HB-01 | 16 × 16 | 0.0140 | 0.0490 | 60.2 |

| HB-02 | 30 × 30 | 0.0085 | 0.0250 | 55.4 |

| HB-03 | 30 × 30 | 0.0106 | 0.0227 | 46.5 |

| HB-04 | 60 × 60 | 0.0072 | 0.0090 | 30.5 |

| HB-05 | 200 × 200 | 0.0020 | 0.0030 | 36.0 |

| Item | Mesh (Wires/ in.) | Wire Diameter (in.) | Width of Opening (in.) | Open Area (%) |

|---|---|---|---|---|

| HC276-01 | 6 × 6 | 0.0470 | 0.1200 | 51.8 |

| HC276-02 | 8 × 8 | 0.0320 | 0.0930 | 55.4 |

| HC276-03 | 10 × 10 | 0.0250 | 0.0750 | 56.3 |

| HC276-04 | 12 × 12 | 0.0230 | 0.0600 | 51.8 |

| HC276-05 | 12 × 12 | 0.0160 | 0.0670 | 64.5 |

| HC276-06 | 12 × 12 | 0.0150 | 0.0680 | 66.6 |

| HC276-07 | 14 × 14 | 0.0200 | 0.0510 | 51.0 |

| HC276-08 | 16 × 16 | 0.0180 | 0.0450 | 50.7 |

| HC276-09 | 16 × 16 | 0.0090 | 0.0535 | 73.3 |

| HC276-10 | 20 × 20 | 0.0230 | 0.0270 | 29.2 |

| HC276-11 | 20 × 20 | 0.0160 | 0.0340 | 46.2 |

| HC276-12 | 20 × 20 | 0.0090 | 0.0410 | 67.2 |

| HC276-13 | 24 × 24 | 0.0140 | 0.0280 | 44.2 |

| HC276-14 | 30 × 30 | 0.0130 | 0.0200 | 37.1 |

| HC276-15 | 30 × 30 | 0.0090 | 0.0240 | 53.1 |

| HC276-16 | 40 × 40 | 0.0100 | 0.0150 | 36.0 |

| HC276-17 | 40 × 40 | 0.0090 | 0.0160 | 41.0 |

| HC276-18 | 40 × 40 | 0.0075 | 0.0180 | 49.0 |

| HC276-19 | 50 × 50 | 0.0090 | 0.0110 | 30.3 |

| HC276-20 | 60 × 60 | 0.0072 | 0.0090 | 30.5 |

| HC276-21 | 60 × 60 | 0.0044 | 0.0123 | 54.2 |

| HC276-22 | 80 × 80 | 0.0070 | 0.0060 | 19.4 |

| HC276-23 | 80 × 80 | 0.0010 | 0.0085 | 46.2 |

| HC276-24 | 100 × 100 | 0.0010 | 0.0060 | 36.0 |

| HC276-25 | 120 × 120 T | 0.0040 | 0.0043 | 27.0 |

| HC276-26 | 180 × 180 | 0.0020 | 0.0036 | 41.0 |

| HC276-27 | 200 × 200 | 0.0023 | 0.0027 | 48.0 |

| HC276-28 | 200 × 200 | 0.0020 | 0.0030 | 36.0 |

| Item | Mesh (Wires/ in.) | Wire Diameter (in.) | Width of Opening (in.) | Open Area (%) |

|---|---|---|---|---|

| HX-01 | 10 × 10 | 0.0250 | 0.0750 | 56.3 |

| HX-02 | 18 × 18 | 0.0090 | 0.0470 | 70.4 |

| HX-03 | 20 × 20 | 0.0160 | 0.0340 | 46.2 |

| HX-04 | 50 × 50 | 0.0030 | 0.0170 | 72.3 |

| HX-05 | 60 × 60 | 0.0075 | 0.0090 | 30.5 |

Hastelloy C276 woven mesh chemical composition

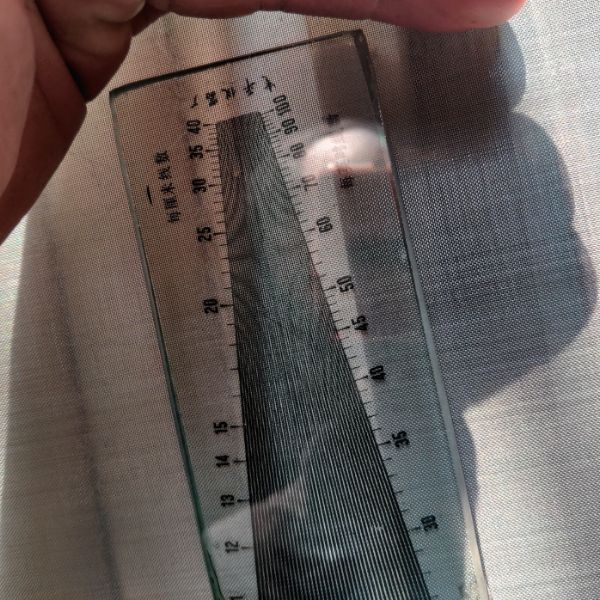

Hastelloy woven mesh thickness inspection

Hastelloy C276 woven mesh aperture inspection

Hastelloy C276 woven mesh width inspection

Hastelloy woven mesh