Boedon, Weaving for Sieving & Filtering

Surface treatment is a processing technology that improves the physical and appearance properties of metal surface through a series of operations on the woven mesh surface, which can be achieved by spraying, electroplating and other methods. Our common surface treatment methods for woven wire mesh are as shown below.

Epoxy coating is a coating compound consisting of an epoxy resin and a polyamine hardener (also known as a catalyst). Electrostatic spraying method is adopted to absorb special epoxy resin powder onto woven wire mesh made of different materials. Through a certain temperature ant time, the epoxy resin powder is melted and covered on the woven mesh surface to form a dense protective coating. Epoxy coated woven mesh can be used as the support layer of hydraulic filters and air filters to filter out particulate impurities in the system and maintain the cleanness of hydraulic and air filtration systems.

PTFE coating, also known as polytetrafluoroethylene coating, is a durable fluoropolymer thin film coating. Woven wire mesh with PTFE coating can effectively prevent the passage of water molecules, thereby separating water from various fuels and oils. It is often used for filtering liquids and gases, and is generally used on the surface of separator filter elements.

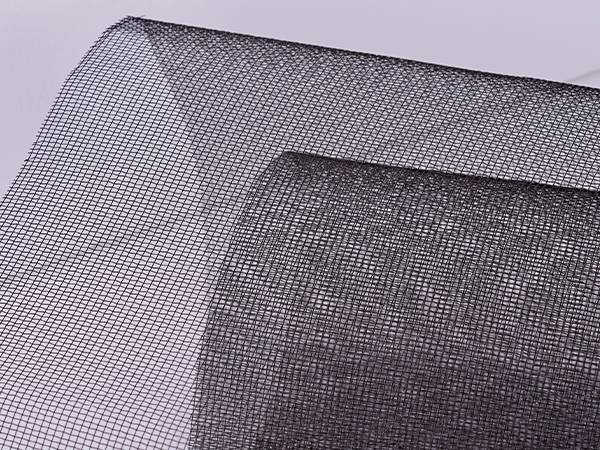

Blacked wire mesh is a type of stainless steel or copper wire mesh that is electrostacially sprayed with a black material to provide better EMI shielding performance, higher transparency and visual effect. It is often used in military, mechanical, pharmaceutical and other industries.

Tinned copper is a process that applies a layer of metal tin coating on the surface of copper wires to prevent copper wire from being exposed to air and easily oxidized to form verdigris. Verdigris has poor electrical conductivity and will increase resistance. Tinned copper is relatively soft and has good electrical resistance. Besides, it has better corrosion resistance and oxidization resistance than copper.

Galvanized copper is a process that applies a layer of zinc coating on the copper to improve its corrosion resistance. This process involves immersing copper material into a zinc solution and then applying an electric current to deposit a layer of zinc on the surface of the copper, producing a more rust and corrosion resistant material called galvanized copper. This makes it an ideal choice for outdoor and marine environments.